Explosion-proof electric butterfly valves are essential components in industries where safety and reliability are paramount, especially in environments prone to flammable gases or dust. As the demand for such valves increases, manufacturers are continuously innovating to provide high-performance, durable, and safe solutions. In this article, we will explore the importance of explosion-proof electric butterfly valves, the key factors in selecting a manufacturer, and the role these valves play in industrial operations.

What is an Explosion-proof Electric Butterfly Valve?

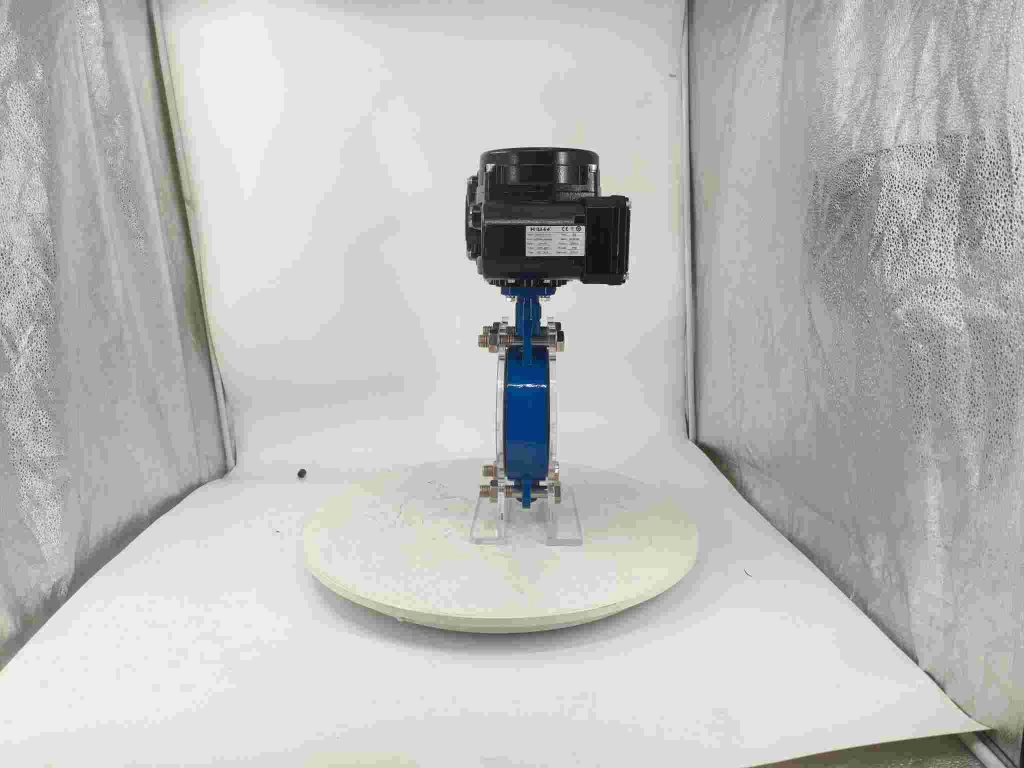

An explosion-proof electric butterfly valve is a type of valve designed to regulate the flow of materials like liquids, gases, or powders in systems that operate in hazardous environments. These valves are typically used in industries such as oil and gas, chemicals, pharmaceuticals, and mining, where the presence of combustible substances makes safety a critical concern. The “explosion-proof” designation means that these valves are built to prevent the ignition of explosive atmospheres caused by electrical sparks or heat. They achieve this by housing the electrical components in a way that contains any potential sparks or heat that could trigger an explosion. These valves combine the operation of a traditional butterfly valve (which has a disc that rotates to control flow) with an electric actuator, allowing for automated and precise control over the valve’s movement.

Leave a Reply