The WCB Explosion-proof Electric Butterfly Valve is an essential component in modern industrial systems, offering reliable performance in environments where safety is of utmost importance. With the increasing need for efficient flow control in hazardous environments, these valves have gained popularity across various industries, including chemical, petroleum, and mining. This article will explore the key features, advantages, and applications of WCB Explosion-proof Electric Butterfly Valves, providing insight into their role in maintaining safety, efficiency, and reliability.

Understanding WCB Explosion-proof Electric Butterfly Valves

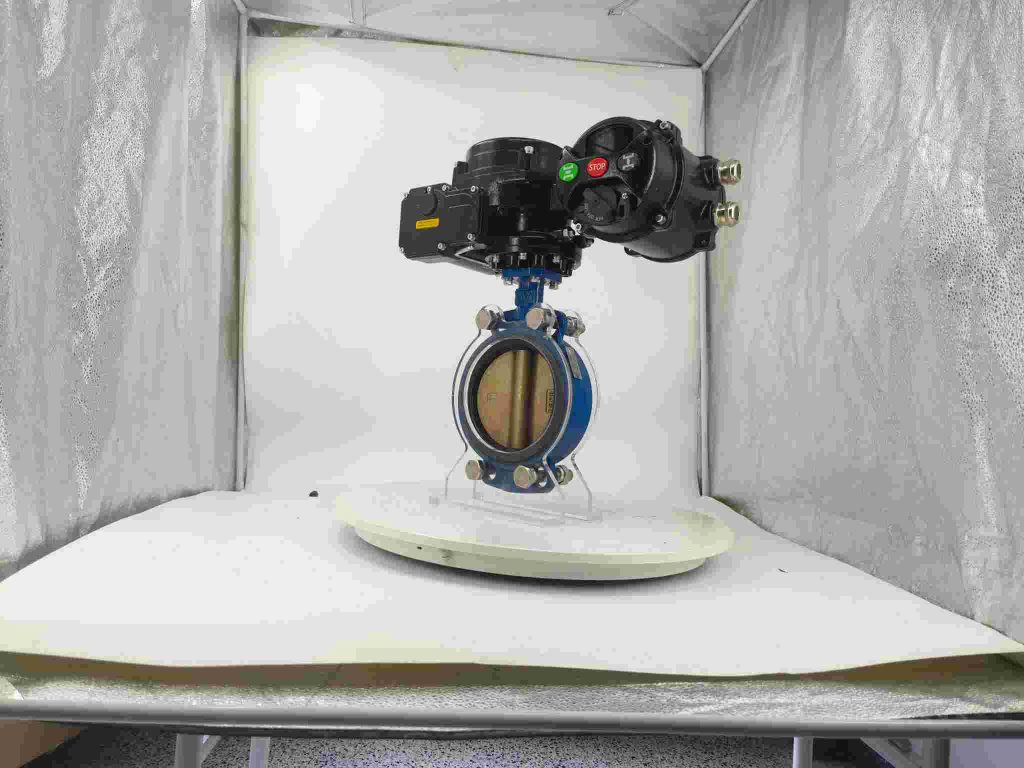

A WCB Explosion-proof Electric Butterfly Valve is a type of valve that utilizes an electric actuator to control the flow of fluids or gases. The valve itself features a rotating disc, or “butterfly,” that opens or closes to regulate the flow within a pipeline. The acronym “WCB” refers to the material of the valve body, which is made of a high-strength carbon steel alloy that offers excellent durability and resistance to wear and tear. The explosion-proof characteristic ensures that the valve can operate safely in hazardous environments where there is a risk of explosions due to volatile gases or chemicals.

Leave a Reply